Interpretation of TPU film industr

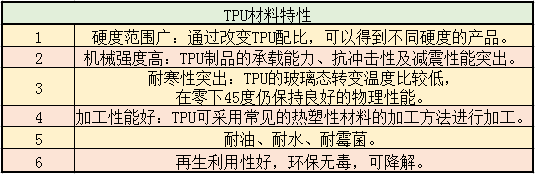

TPU is the abbreviation of "Thermoplastic PolyUrethane". The Chinese name is thermoplastic polyurethane elastomer. It is a high molecular polymer obtained by polymerization of diisocyanate, chain extender and macrodiol. It is an emerging organic polymer material. TPU has the following characteristics that are unmatched by other plastic materials:

Introduction to TPU film

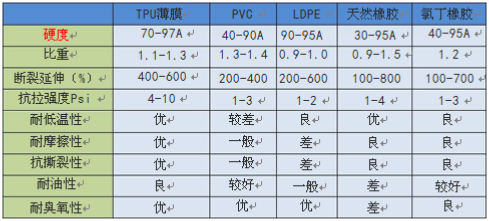

TPU film has excellent properties such as high strength, high toughness, wear resistance, oil resistance, cold resistance, aging resistance, environmental protection, non-toxicity and degradability which are unmatched by other plastics and rubber. It is also waterproof, moisture-proof, wind-proof, cold-proof, anti-bacterial and UV-resistant. Excellent performance, can be applied in many industrial and civil fields. It is a green film and an ideal substitute for PVC film. The performance of TPU film compared with other polymer materials is as follows:

It can be seen from the above table that the comprehensive performance of the functional TPU film is obviously superior to that of the general plastic and rubber film. TPU film is divided into two major categories: polyester and polyether. Among them, polyester products have good heat resistance and chemical resistance, and are widely used in the replacement of PVC products. Polyethers have better low temperature resistance, hydrolysis resistance, and mildew resistance, and are widely used in related products in contact with water.

TPU films are divided into blown film series and casting series due to their different manufacturing processes, which are applied to different fields. The performance of the film produced by the casting process and the blown film process is as follows:

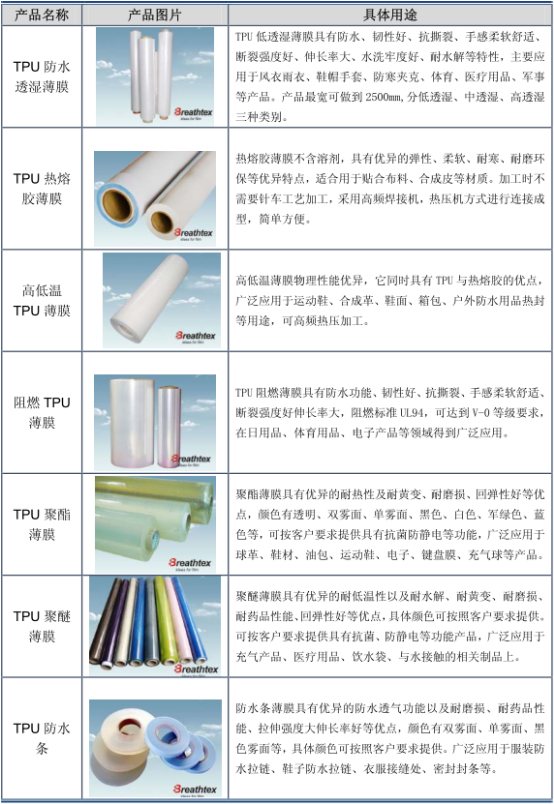

The properties and uses of some TPU films are as follows:

TPU film market

Since 2007, as the footwear, machinery, pipe, automotive, construction and other industries have developed rapidly, and more and more wear-resistant materials use TPU, the global demand for TPU is growing, with a compound annual growth rate of 6.6%. .

According to the statistics of the British IAL consulting company, the global consumption of TPU in 2007 was 384,300 tons, and in 2010 it was 465,500 tons.

As the unit price of TPU particles gradually decreases, the cost performance of TPU materials gradually emerges. At the same time, the superior performance and environmental protection characteristics of TPU will make it a substitute for PVC. In the future, the compound annual growth rate of TPU industry will reach about 10%. The demand for global TPU materials will reach 750,000 tons, and the demand for TPU film materials will reach 150,000 tons.

At present, the annual consumption of domestic TPU film market is about 30,000 tons, and high-end TPU film is still mainly imported. As domestic environmental awareness continues to increase, TPU applications will become more widespread. Among them, the areas with faster growth rate are in terms of shoes, clothing and medical supplies. It is expected that the annual growth rate will reach 15% to 20% in the next five years.

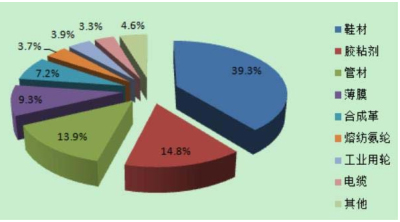

TPU has excellent mechanical properties such as high strength, high elasticity, high wear resistance and high flexibility. It also has oil, solvent and general chemical resistance, which determines the multi-purpose properties of TPU. Targets, adhesives, pipes, films and other fields. The TPU application market is distributed as follows:

TPU film material

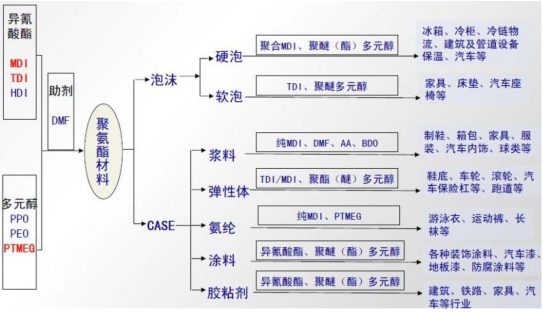

The main raw material of the TPU film is polyurethane particles. Polyurethane raw materials are the most critical part of the polyurethane industry chain. The main raw materials of polyurethane include isocyanate and polyether/polyester polyol, and the auxiliary materials include solvents, catalysts, surfactants and flame retardants.

Isocyanate and polyether/polyester polyols differ from most other chemical products in that they have high technical barriers, especially isocyanates (also known as black, MDI and TDI). The key technology is only in BASF (BASF Polyurethane Co., Germany) ), Bayer (Germany Bayer Material Technology Co., Ltd.) and other foreign multinational companies and a few domestic enterprises Wanhua Chemical Group Co., Ltd. (formerly known as Yantai Wanhua Polyurethane Co., Ltd.) in the hands.

Multinational companies have firmly grasped the international polyurethane market through acquisitions and expansions, and presented an oligopoly pattern. Lubrizol's research and quality control of blown film and cast TPU particles is the highest level in the world today. Domestic Wanhua Chemical Group Co., Ltd. and Zhejiang Huafeng New Materials Co., Ltd. are currently catching up, and the share of the isocyanate supply chain is getting larger and larger, and the purity of the products is getting closer to foreign companies such as BASF. The manufacturing technology of domestic companies is steadily improving. The list of polyurethane industrial chains and products is as follows:

TPU film company

(1) Taiwan Dingji Chemical Industry Co., Ltd.

Established in Kaohsiung, Taiwan in 1981, Dingji Chemical is the world's largest manufacturer of TPU film and has a global leading position in TPU film applications. Its TPU film products mainly include: waterproof and moisture permeable film, microporous gas permeable film, TPU leather, hot melt adhesive film series, non-yellowing hot melt adhesive film, shoe material application series, non-yellowing series, medical grade moisture permeable film, Film for bulletproof glass, TPU foam series, elastic band series, etc.

(2) Dongguan Xionglin New Material Technology Co., Ltd.

Xionglin New Materials was established in July 2006. The TPU film produced mainly consists of casting. It has a number of TPU casting film production lines with a monthly output of 500 tons. It is the largest TPU casting film supplier in Asia. The product field is mainly in shoe materials, ready-to-wear, medical supplies, sports equipment, inflatable products, water amusement products, fashion accessories, electronic products, printing, trademarks, luggage handbags, water bags, fittings, waterproof zippers, waterproof rubber strips, etc.

(3) Zhongshan Boruisi New Materials Co., Ltd.

Boruis was founded in 2007 and listed on the New Third Board in 2015. Its TPU film products include a flow-through and blown film process. The monthly output exceeds 15 million square meters, the thickness of TPU film can be 0.01mm-2mm, and the width can be 0.5m-2.5m. Bo Ruisi's main business is the development, production and sales of functional TPU films.

TPU film development trend

1.TPU film replaces PVC

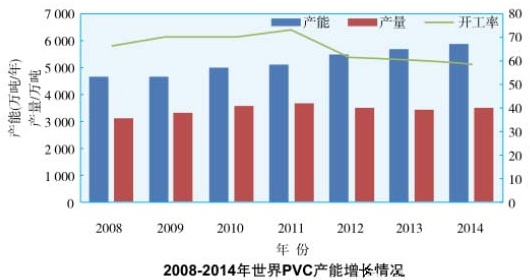

Polyvinyl chloride (PVC) is one of the world's first industrialized resin varieties, and is the second largest plastics in the world after polyethylene. In 2013, about 150 producers from 50 countries and regions produced PVC in about 380 production plants with a total capacity of 57.46 million tons/year, a production of about 34.8 million tons and an output value of about 40 billion US dollars.

After the rapid growth of PVC production capacity in China in the early 21st century, the growth rate began to slow down after 2008, and the production capacity reached more than 30 million tons per year by 2015. However, affected by overcapacity in the industry, the average operating rate of the PVC industry is hovering at 55% to 60%. At the same time, because PVC will release highly toxic dioxins in the production process, and PVC products will have certain carcinogenic effects on the human body, its recycling Utilization is very difficult and therefore very harmful to human health and the environment.

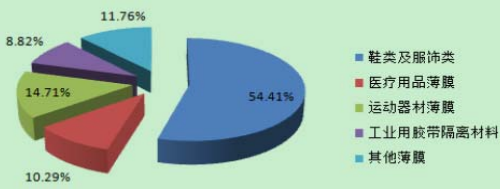

Since 1999, the EU has taken measures to ban the use of PVC-based related products, such as children's toys, shoe materials, etc., TPU as the best substitute for PVC, with TPU as a shoe material, footwear products have become the European and American markets. Pass. According to statistics, the proportion of TPU film applied to shoe materials has reached 54.41%. The market distribution of TPU film applications is as follows:

According to the international polyurethane network data forecast, TPU will gradually replace 80% of PVC film market in the next 5 years.

2. Demand for functional apparel is strong

Due to the waterproof and breathable characteristics of the TPU film, it fully satisfies the dual requirements of outdoor functional clothing, which is both comfortable and protective, and greatly increases the added value of the clothing. TPU film has been widely used in outdoor functional clothing such as ski wear and jackets, as well as functional fabrics for special equipment such as professional wear and military uniforms.

At present, the outdoor products market of outdoor functional apparel is developing rapidly. The total annual growth rate of outdoor retail sales in China from 2005 to 2013 is 42.9%. In 2013, it reached 18.05 billion yuan, up 24.3% year-on-year. In 2009, it has reached more than 5 billion.

It is expected that in the coming period, China's outdoor products market will continue to maintain a good momentum of rapid growth, and the demand for TPU film will continue to grow rapidly.

3. New situation of automobile supporting industry

The domestic automobile supporting industry is huge in scale. High-performance polyurethane is a new generation of environmentally-friendly artificial synthetic leather material. It has excellent strength, scratch resistance and wear resistance. It has become an indispensable material for automotive interiors, including only one automotive interior. In 2010 and 2011, the market size reached 59.32 billion and 65.55 billion yuan respectively. The development of environmentally-friendly synthetic leather will drive the substantial increase in demand for TPU materials.

At present, synthetic leather products are widely used by Toyota, Nissan, Citroen, China FAW, China Second Automobile, Hainan Mazda, Chery and other automobile manufacturers. As the high-end field of TPU material application, the automotive interior industry will open up a new situation for its development.

4. Broad prospects in the medical field

The medical and health field mainly applies TPU film to surgical gowns, medical gloves, medical mattresses, ice bags, bandages, plasma belts, condoms, wound dressings, artificial organs and the like. For example, waterproof and breathable TPU medical gloves can provide excellent water vapor permeability, antibacterial and comfort; TPU microporous and hydrophilic membranes can make wound dressings have good ventilation and absorption functions, which can effectively block active groups in drugs. Unnecessary diffusion can ensure that the active ingredients act on the skin at a certain rate; TPU has good compatibility with human blood and tissues, and TPU is used to make materials for blood vessels and artificial organs.

At present, medical devices made of TPU have been widely used abroad. Due to the aging of China's population, new materials such as TPU will be widely used. Based on the 27% growth rate of China's medical device industry, the profitability of medical-grade TPU is huge.

In summary, TPU film as a stable quality, non-toxic and non-polluting new plastic materials will be widely used in various fields of production and life. In 2015, the total domestic production of TPU film was about 45,000-55,000 tons, including TPU film and TPU hot melt film. According to the unit consumption estimate and market participants, the consumption of TPU in the film field was about 41,000 tons. It is estimated that China's TPU film market will grow at an average annual rate of 12% from 2015 to 2019 and reach 4 billion yuan in 2019.