粘接力,Adhesion

粘接力是当两类不相似的物体接触时所产生的相互作用力,在分子水平上说,粘接力是基于物理和某些情况下的化学粘接的基础上的。粘接强度取决于胶水的类型。

Adhesion is the interaction that develops between two dissimilar bodies when they are in contact. At the molecular level, adhesion is based on physical and in some cases chemical bonding. The strength of adhesion depends on the type of adhesive.

轻微的压力可以增加压敏胶水的粘接力。24至72小时后可以达到最终粘接强度

Pressure sensitive adhesives build up adhesion under light pressure. The ultimate bonding strength is reached after 24 ~ 72 hours.

测试方法:“剥离力测试”和“初粘力滚球测试” 具体数据,请参考其产品资料。

Test method: “peel adhesion test” and "initial tack - rolling ball" . For specific data, please refer to TDS.

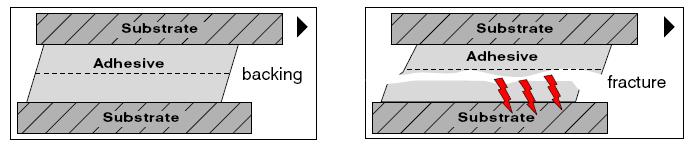

粘接失败是描述胶水从基材或者被粘物表面脱离的情况。其他的基础粘接失败机理有“内聚力失效”——指胶水从中间断裂。

Adhesive failure describes the separation of adhesive either from backing or from the substrate. The other basic failure mechanism of an adhesive bond is “cohesive failure” which refers to a fracture in the middle of the bulk adhesive.

胶粘剂,Adhesive

胶水为用于把不同的材料连接在一起的聚合物材料。胶水可以有很多种分类方法,例如,应用模式,化学组分,成本,和对于各种最终产品粘着适宜性。

Adhesives are polymer materials that are used to join dissimilar materials. Adhesives may be classified in many ways, e.g. by mode of application and setting, chemical composition, cost, and suitability for various adherents and end products.

“压敏胶”(PSA)是一种胶水,可以在室温相对干燥的状态下长期具有初粘性。

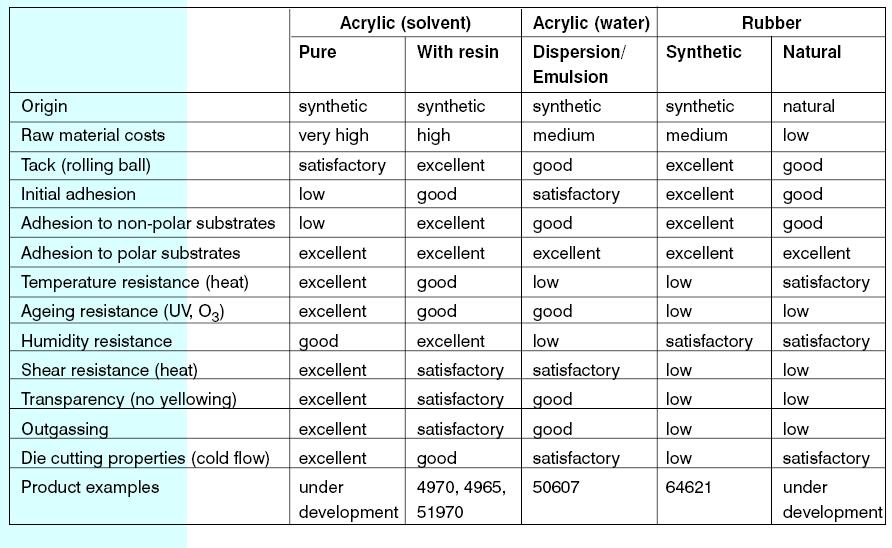

基本性质对比,请参考以下的表格。

The term "pressure sensitive adhesive" (PSA) is used to describe adhesives that are permanently tacky in dry form at room temperature. The most common pressure sensitive adhesives are acrylics, natural rubber/resin, and synthetic rubber/thermoplastic rubber. For comparison of basic properties, please refer to the following table:

抗老化,Ageing resistance

经过一段时间和一定条件,胶带表现出的可靠性。根据使用的胶水系统,压敏胶通常用做长期应用。此项表现通过以下情况反映出来:

- 臭氧(O3), 氧气 (O2) - 紫外线: 与透明的被粘物有关,例如玻璃或者PC;处于直接室外暴露,胶水或者基材的发黄或者变色。 (例如,窗户条的固定).

- 温度 - 湿度, 水

- 不同的化学品

Degree of reliable performance of the tape over time, under certain conditions. Depending on the adhesive system being used, PSA tapes are often usable for permanent applications. This permanence is reflected by the resistance of the adhesive against:

- Ozone (O3), Oxygen (O2)

- UV light: relevant for transparent substrates such as glass or PC; under direct exposure, yellowing or discoloration of the adhesive or backing (e.g. window bars).

- Temperature - Humidity, water

- Different kinds of chemicals …

通常丙烯酸胶水比橡胶胶水更适合承受这些环境影响,能够经历很多年保持长期而可靠的功能性。

Generally acrylic adhesives are much better suited to withstand these environmental influences than rubber adhesives and can maintain their permanent, reliable functionality over many years.

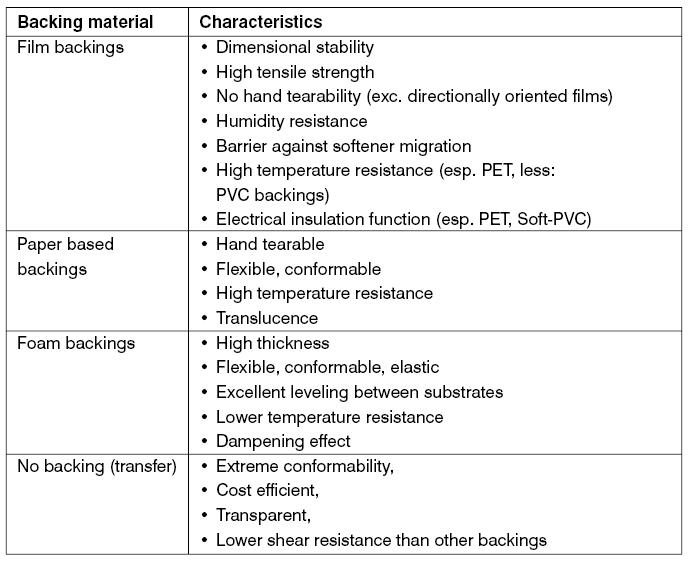

基材, Backing

“支撑”胶水的材料。基材也可以增强压敏胶带,提高操作和制程性能。 最常用的基材类型有:

1. 塑料基材 (如 PET聚酯, PP聚丙烯, PVC聚氯乙烯, PE聚乙烯)

2. 纸基的基材 (如绵纸,无纺布)

3. 泡棉基材 (如 PU聚氨酯泡棉, PE聚乙烯泡棉, PVC聚氯乙烯泡棉)

4. 织物 (如人造织物, 棉花, PA, PET) 一种特殊的压敏胶带的类型为无基材压敏胶带,此胶带没有基材。胶水直接涂布在离型纸上。

5. 其他不太典型的基材的材料有 布,织物,金属等。

Materials which “carry” the adhesive. The backing also reinforces the PSA tape and improves handling and processing properties. Most commonly used backing types are:

1. Film backings (e.g. PET, PP, PVC, PE)

2. Paper based backings (e.g. non-woven, tissue)

3. Foam backings (e.g. PU-, PE-, PVC-foams)

4. Woven cloth (e.g.rayon, cotton, PA, PET) A specialty PSA tape type is a transfer PSA tape which has no backing. The adhesive is directly coated on the liner.

5. Other less typical backing materials are cloth, fabrics, metals etc. Overview of backing material characteristics:

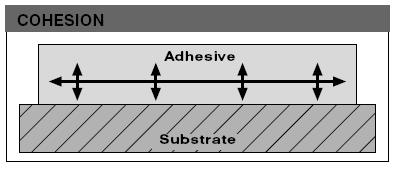

内聚力, Cohesion

内聚力是描述胶水的内部强度。主要决定了胶带的保持力(抗剪切力) 测试方法“抗剪切力测试”

Cohesion describes the inner strength of the adhesive. It mainly determines the holding power (shear resistance of the tape. Test method: “shear resistance test”.

内聚力失效使胶水残留在胶带和被粘物表面的两边,显示出胶水内部断裂。用手指简单检查:被粘物和胶带两边都有粘性。

Cohesive failure leaves adhesive residue on both the PSA tape backing and the laminated surface, showing that the adhesive broke internally. Easy check with the finger: it sticks on both the substrate and the tape.

基本来说: 高内聚力 = 高耐温性 = 较低的初粘性 = 高保持力

Basically: high cohesion = higher temperature resistance = lower tack = high holding power

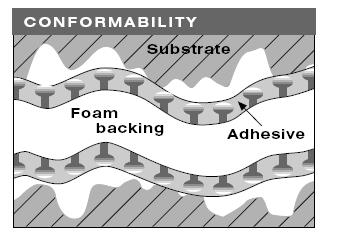

服帖性, Conformability

压敏胶带的基材对粘接到弯曲,粗糙和不规则表面有影响。服帖的基材可以提高胶水和被粘物的接触面积。 泡棉基材本身就很服帖,可以在两个粘接被粘物中间补偿表面的不规整。

The backing of a PSA tape influences its ability to adhere to curved, rough or irregular surfaces. Conformable backings increase the contact area of adhesive and substrate. Foam backings are inherently conformable and can therefore compensate for surface irregularities between the two bonding substrates.

尺寸稳定性, Dimensional stability

和离型纸的吸湿性有关。尺寸稳定性可以保持离型纸不会出现由于吸收水汽而产生的不规则的表面或者是尺寸改变。

尺寸稳定的离型纸主要有: PE 涂层的离型纸,塑料薄膜离型纸。

Correlates with humidity of liners. Dimensional stability prevents the liner from showing an irregular surface or dimensional change due to absorption of moisture.

Dimensionally stable liners are mainly PE coated paper liners and Film liners.

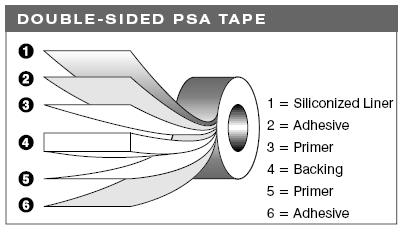

双面胶带, Double-sided tape

胶水涂布在基材的两边。通常一层胶水由离型纸覆盖(闭面)为了压敏胶带可以卷成卷装。在双面胶带的生产中,基材经常经过底涂剂的预处理使胶水和基材达到最大的固着能力。另外还有无基材的双面胶带。

Comprised of a backing material coated with adhesive on both sides. Usually one adhesive layer is covered with a release liner (closed side) in order to wind the PSA tape in roll form. In d/s tape production the backing is often pre-treated with a primer to enable a maximum anchorage between backing and adhesive. Transfer tape.

鱼眼, Fish eyes

在一卷胶带中不同胶带层中间进入空气而造成的视觉影响。

Optical effect caused by entrapment air between different tape layers on a roll.

泡棉, Foam

整个结构中包含很多小孔或者小单元的材料,通常的泡棉包括:

丙烯酸泡棉

乙烯-乙酸乙烯酯泡棉(EVA泡棉)

聚氨酯泡棉 (PU泡棉)

聚乙烯泡棉 (PE泡棉)

Material containing small holes (cells) distributed throughout the entire body. Most common foams are:

-AC-foam Ethylene

-vinylacetate

-foam (EVA) Polyurethane

-foam (PU) Polyethylene-foam (PE)